Impinj Enduro Bonding Technology

The strength of the connection between a tag chip and its antenna is at the heart of inlay reliability. Impinj Enduro bonding technology, features large contact pads for attaching antennas to elevate tag reliability and ensure unparalleled durability, surpassing conventional bumped designs.

Impinj Enduro strengthens chip-to-antenna connection

At the center of a RAIN RFID tag lies the critical bond between the tag chip and the inlay antenna, which impacts the tag’s reliability. An insufficient antenna connection can result in erratic tag performance and vulnerability to environmental factors such as humidity.

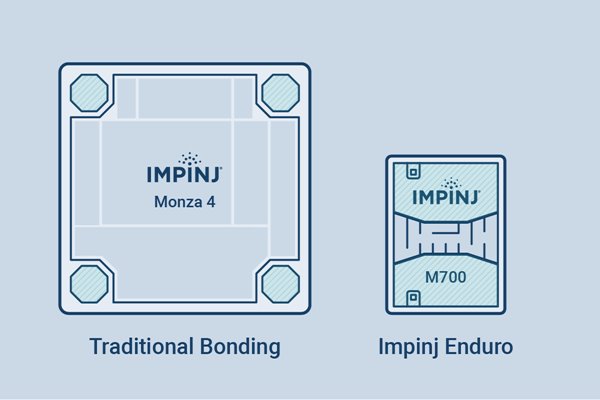

The conventional bonding method relies on four small contact bumps, one at each corner of a tag chip, serving as attachment points for the antenna. This method demands precision in chip placement and secure antenna contact – a challenge given the bumps’ limited surface area.

Impinj Enduro bonding technology replaces conventional bumps with two large, robust connection pads that cover the width of the chip, enhancing the tag chip’s contact area and supporting a stronger, more dependable bond with an antenna.

Introducing Enduro V2 technology

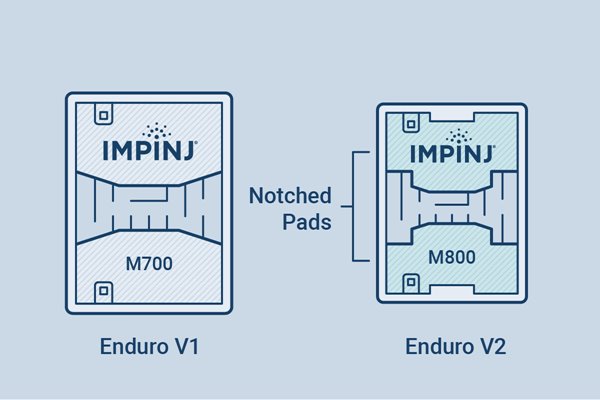

First introduced alongside the Impinj Monza R6 series, Impinj Enduro was improved following the release of the Impinj M700 series tag chips. Since then, our bonding pad design has continued to evolve to keep pace with Impinj tag chip advancements. Impinj Enduro V2, included in the Impinj M800 series tag chips, further strengthens the chip-to-antenna connection by increasing the chip’s bondable surface area – even with the Impinj M800’s smaller size.

Impinj Enduro V2 introduces notches to the design of the bonding pad, augmenting the pad’s sidewall surface area and enhancing adhesive flow and bond strength. This meticulous attention to detail not only allows us to offer our smallest chip yet, but also enhances manufacturability.

Impinj Enduro enables high-performance RAIN RFID tags

Increased tag strength and longevity

The Impinj Enduro V2 bonding pad design strengthens the chip-to-antenna connection for enhanced durability over the lifespan of the tag.

Reliable and consistent tag assembly

The bonding pad’s large contact area makes it easier to attach a tag chip to an antenna, and prevents misalignment during the inlay manufacturing process.

Sustainable and efficient tag production

With Enduro V2, we can manufacture more chips per wafer, reducing material requirements and increasing production efficiency.