Global Tire Manufacturer Gets Rolling with Kathrein and Impinj

A top-tier enterprise is using RAIN RFID to streamline tire production and increase driver safety by tracking tires in the manufacturing facility, on the assembly floor – and beyond.

Streamlining production and ensuring safety

Tire manufacturers are always looking for ways to ensure their production processes are streamlined and error-free. Delivering the wrong tire to the vehicle assembly line or mounting a tire incorrectly on a finished vehicle body can cause production processes to grind to a halt, wasting precious time and delaying deliveries. Or worse, manufacturing and assembly errors can compromise a car’s safety, putting drivers and passengers at risk on the road.

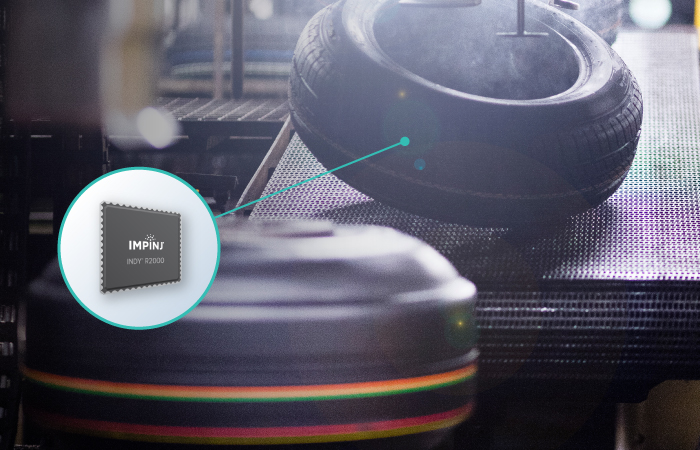

IoT solutions provider and Impinj gold partner Kathrein Solutions GmbH helped one top-class tire manufacturer solve these problems by leveraging the power of RAIN RFID, a wireless communication technology that uses radio waves to identify, find, and track objects. The global tire enterprise used the Kathrein ARU 2400 RAIN RFID reader – powered by Impinj RAIN RFID reader chips – as part of an over-arching IoT solution to gain insight into their operations from the manufacturing facility all the way to the dealer.

With the Kathrein and Impinj solution, the tire manufacturer can:

- Track the location and verify the attributes of tires throughout manufacturing facilities

- Monitor the tire mounting process during vehicle assembly

- Follow each tire throughout its life, even after it leaves the assembly plant

Kathrein ARU 2400 reader zeroes in on safety

This manufacturer of performance tires for high-end automobiles relies on Kathrein ARU 2400 RAIN RFID readers throughout its 20 tire manufacturing plants worldwide to ensure a smooth production process and – ultimately – safe, reliable tires. Here’s how the Kathrein and Impinj solution works:

- Tags featuring Impinj RAIN RFID tag chips are embedded in car tires during the manufacturing process, allowing the enterprise to identify each tire by size, profile, purpose, and other attributes.

- Kathrein ARU 2400 RAIN RFID readers featuring Kathrein SmartShelf or WRA 6060 antennas, installed at points throughout the warehouse, read the tires’ tags. The battery-free tags are energized by the radio waves from the Kathrein readers.

- This enables workers to confidently match the right types of tires with the right jobs, and the tires are correctly routed to the assembly line.

- During the tire mounting process, multi-antenna Kathrein RAIN RFID readers positioned at the assembly line ensure an accurate read of the tagged tires – even as the tires rotate during placement.

RAIN RFID: Offering Insight During Production and Beyond

Kathrein’s global tire manufacturing customer tapped the power of RAIN RFID by combining the Kathrein 2400 RAIN RFID reader and the Impinj platform, improving efficiencies in its facilities and ensuring its product is as safe as possible.

The right tires at the right time

Tires come in a mind-boggling array of sizes and uses, and each model of car requires a specific type. Mounting the wrong type of tire to a car could cause safety issues down the line. Each Impinj RAIN RFID tag chip embedded in a finished tire includes tire identification data, which can be quickly and easily visualized via Impinj-powered Kathrein readers and associated software. This means plant workers can zero in with confidence on the exact tires they need for each car.

Guaranteed precision during the mounting process

Mounting a tire on a vehicle can be a complicated process. The relative position of the tire’s embedded RAIN RFID tag changes as the wheel rotates during the mounting process. Kathrein readers positioned along the assembly line include multiple embedded antennas that ensure the RAIN RFID tag remains detected throughout the process. The result? Assurance that tire placement is precise, seamless, and without error.

A lifetime of insight

Using RAIN RFID in tires means big benefits for manufacturers and automobile assemblers – but the advantages don’t end there. As long as a RAIN RFID tag remains embedded in a tire, dealers and parts sellers using RAIN RFID readers can take advantage of a tags’ stored data, giving them actionable insight into maintenance, warranty, and recyclability throughout the life of the tire.

- Article tagged as:

Tuesday, February 20, 2024

ABOUT THE PARTNER

Kathrein Solutions GmbH

Kathrein Solutions and its integration partners provide IoT technologies including hardware, software, services and support.

Sign Up for the latest news