Automate tracking of all things moving in a supply chain for next-level agility

Supply chain managers know, speed matters. And today, more than ever, supply chains are disrupted in new and different ways. Supply chain automation solutions built by Impinj partners bring automation and agility to supply chains. When organizations extend an IoT system to include the things moving through the supply chain—they unlock a new level of insights about their operations.

Discover how supply chain automation

is transforming retail and logistics operations

Retail

Achieve full visibility and control with accurate, automated high-speed systems

Logistics

Leverage accurate, automated high-speed systems for peak efficiency

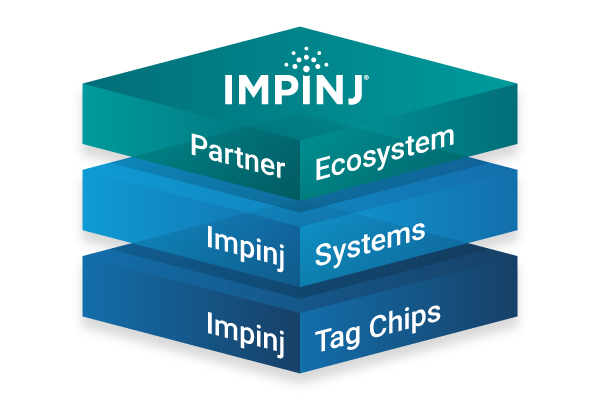

Impinj platform — a foundation for IoT solutions

The Impinj platform lays a foundation for IoT solutions development, extending the Internet’s reach from the cloud, through edge connectivity devices, all the way to physical items. Our broad partner ecosystem uses our platform's best-in-market products, capabilities, and technology to deliver whole products that address business needs. Wirelessly connect everyday items to discover, engage with, and protect them. Easy to deploy and use, our platform delivers performance unequaled by mix-and-match approaches built from other vendors’ products.

How Impinj enables RAIN RFID supply chain automation

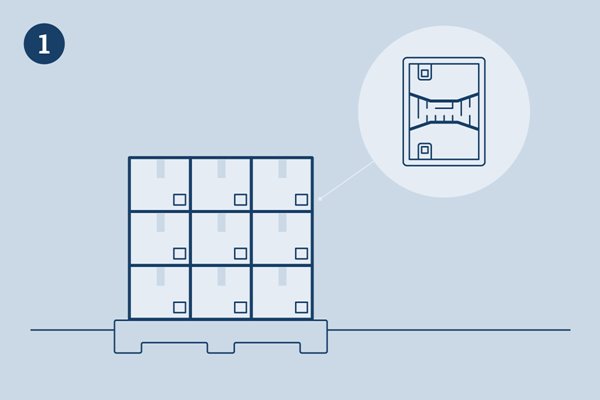

Tag Goods

Attach Impinj-powered RAIN RFID tags to goods and containers. Tags can be read at a distance and without line-of-sight.

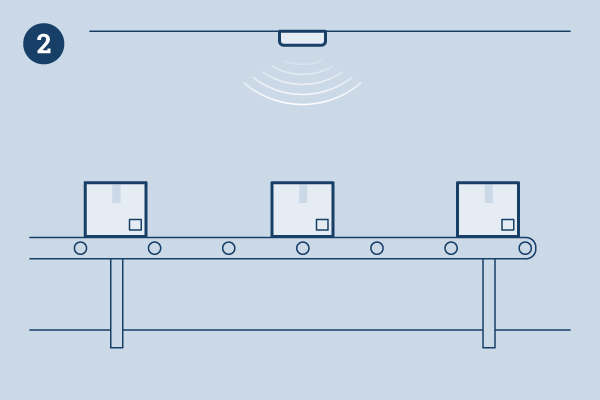

Read Goods

Impinj readers installed on conveyors or doorways read and identify goods and containers as they move in and between facilities.

See Goods

See data about the movement of goods in your existing shipping system and receive alerts when errors occur.

Retail organizations

achieve full visibility and control with accurate, automated high-speed systems

Learn More Track inbound and outbound shipments

Gain visibility into shipments to operate with agility. Unlock next-level efficiency when you know the location of all things moving through your supply chain. Use accurate inventory data across stores and distribution centers to enable omnichannel sales.

Streamline and speed up distribution centers

Read all items, even within closed boxes, to ensure contents are complete and correctly routed along conveyor systems — enabling speedy, streamlined distribution centers.

Eliminate manual shipping errors

Keep customers and stores happy with an error-free distribution system that gets the right items to the right location at the right time — every time.

CUSTOMER STORY

China Outfitters increases operational efficiency with RAIN RFID

With millions of products to manage, China Outfitters needed to make sure their inventory tracking processes—which span several top retail brands—were not slowing them down. With a solution from Impinj partner Hyesoft, China Outfitters increased efficiency in its inventory, shipping and returns procedures 25 times over.

CUSTOMER STORY

Heilan Home Streamlines Logistics and Retail Operations

Retail and manufacturing company Heilan Home increased efficiency after implementing the Impinj platform for real-time item tracking and inventory location. Since 2014, Heilan Home has worked with Impinj and partner Xindeco to increase the efficiency of its warehouse operations and lower its labor costs.

Logistics organizations

leverage accurate, automated, high-speed systems for peak efficiency

Learn More Track goods moving across all locations

With end-to-end tracking across beltways and conveyors, operators gain visibility into all parts of a supply chain to know where inventory is located and see disruptions as they happen. Unlock next-level efficiency and new insights with visibility into every thing moving within and across all locations in your supply chain.

Streamline and simplify distribution centers

Reading barcodes requires direct line of sight and expensive robots that flip packages to orient them correctly. With a system enabled by Impinj, quickly identify moving items without such limitations as they travel on conveyors, hand trucks, or forklifts. Operate a smart system that streamlines and simplifies operations and identifies every item correctly, every time.

Eliminate picking and shipping errors

Backtracking because of errors is not only costly, it reduces trust in the whole system. Prevent packing and shipping errors with instant audits of items prepared for shipping, and eliminate the need to handle items multiple times. Teams work efficiently and customers get what they expect.

CUSTOMER STORY

SAIC Anji Logistics Halves Inventory Time with RAIN RFID and Drones

SAIC Anji Logistics uses RAIN RFID-powered drones to improve inventory accuracy and cut inventory time in half. The solution from Impinj partner Silion cut inventory tracking time in half and provides nearly 100% accurate inventory data.

Customer Story

Faurecia Creates Factory of the Future with RAIN RFID

Vehicle interior manufacturer Faurecia optimizes production and shipment operations with a RAIN RFID system for real-time asset tracking from Impinj. Faurecia worked with Impinj and partner UBI Solutions to create a RAIN RFID solution that can now be deployed within one week at each new plant. By tagging items that enter the plant and using Impinj readers along the manufacturing line, they optimized their logistics process while eliminating redundant manual steps.